Wireless temperature monitoring systems are much better than old-fashioned manual temperature checks and data logging. These advanced solutions continuously track temperature conditions in real-time, automatically sending data to central platforms where it can be accessed remotely from anywhere.

Accurate temperature control isn’t just a good practice—it’s a critical requirement in places storing vaccines, pharmaceuticals, biological samples, and other materials that need specific temperatures. If the temperature goes off for even a moment, it can ruin all the stored items, leading to huge financial losses and putting patient safety at risk.

Unfortunately, many organizations still rely on outdated methods to monitor temperatures. They don’t realize that these old systems are making them vulnerable. Manual temperature checks, delayed alerts, and gaps in data collection can lead to compliance issues and spoilage of products.

In this article, we’ll discuss 6 signs that indicate you need to switch to wireless temperature monitoring systems. If your facility shows any of these signs, it’s possible that your current temperature monitoring technology is endangering your products, compliance status, and operational efficiency. By identifying these upgrade signs, you’ll be taking the first step towards finding a more dependable automated solution that keeps your valuable inventory safe 24/7.

1. Are They Struggling With Delayed or Inaccurate Temperature Alerts?

Manual temperature monitoring creates critical gaps in alert systems. Staff members checking thermometers every few hours may miss temperature excursions that occur between rounds, leaving vaccines or medications exposed to unsafe conditions for extended periods before anyone notices the problem.

Traditional data loggers compound this issue by storing information locally. The data sits dormant until someone physically downloads and reviews it—often days or weeks after an incident occurs. By the time staff discover a temperature breach through these outdated systems, the damage has already happened and products may be compromised beyond recovery.

Wireless systems eliminate these dangerous delays through automated notifications:

- Real-time alerts reach designated personnel within seconds of temperature deviations

- Email and text notifications ensure multiple team members receive warnings simultaneously

- Continuous monitoring captures every fluctuation, not just periodic snapshots

- Back-to-base alarm systems trigger immediate responses regardless of time or day

The speed of these automated notifications directly impacts product safety. A refrigerator malfunction at 2 AM won’t go unnoticed until morning rounds—wireless systems wake the on-call staff immediately. This rapid response window often means the difference between salvaging inventory and disposing of thousands of dollars worth of temperature-sensitive materials.

Vaccine storage illustrates this urgency perfectly. The CDC requires vaccines to remain between +2°C to +8°C, and even brief excursions outside this range can reduce potency or render doses completely ineffective. When a wireless system detects temperature deviations crossing the +8°C threshold, it sends instant alerts that allow staff to transfer vaccines to backup storage before they reach unsafe temperatures. Manual systems simply cannot provide this level of protection.

In contrast, real-time temperature monitoring offers a robust solution to these challenges. By continuously tracking temperature changes and sending immediate alerts when thresholds are breached, these systems ensure that sensitive products are always stored under optimal conditions, thus safeguarding their efficacy and integrity.

2. Is Manual Data Collection and Logging Consuming Excessive Time and Resources?

Manual temperature logging drains valuable staff hours that could be spent on more critical tasks. Traditional monitoring requires personnel to physically check thermometers multiple times daily, record readings by hand or download data from loggers, and then manually review spreadsheets for any anomalies—a process that can consume 30-60 minutes per location each day.

The labor-intensive monitoring process extends beyond simple data collection. Staff must:

- Walk to each storage unit at scheduled intervals

- Record temperatures accurately without transcription errors

- Transfer handwritten logs into digital formats for record-keeping

- Cross-reference multiple data points to identify potential issues

- Generate reports manually for compliance audits

Human error becomes inevitable when employees handle repetitive data entry tasks. A misread decimal point, a forgotten check during busy periods, or illegible handwriting can compromise the entire monitoring record. These mistakes create gaps in documentation that regulatory bodies flag during inspections.

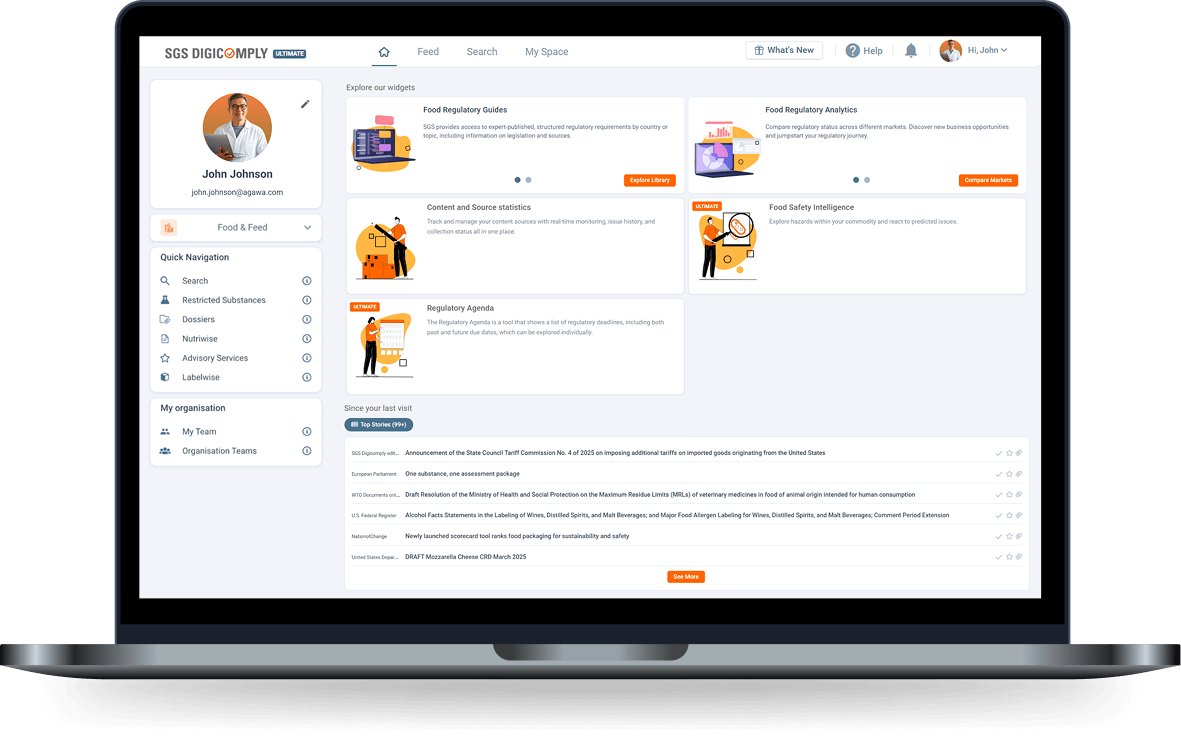

Wireless systems eliminate this burden through automated data collection that runs continuously without human intervention. Sensors transmit readings directly to cloud-based platforms every few minutes, creating comprehensive digital records without staff involvement. The system timestamps each entry and stores data securely, removing the possibility of forgotten checks or recording mistakes.

Automation benefits extend to reporting and analysis. Instead of spending hours compiling weekly or monthly temperature reports, managers access pre-formatted dashboards that visualize trends instantly. The software generates compliance-ready documents at the click of a button, complete with all required data points and timestamps.

Staff workload decreases significantly when monitoring becomes automated. A pharmacy that previously allocated two hours daily to temperature checks can redirect that time toward patient care. Laboratory technicians focus on research rather than walking between freezers with clipboards. The cost savings multiply across organizations with multiple storage locations—what once required a dedicated compliance officer now runs autonomously in the background.

3. Are They Concerned About Compliance With Stringent Storage Guidelines Like Vaccine Cold Chain Management?

Vaccine storage guidelines demand strict adherence to temperature ranges between +2°C and +8°C, with even brief excursions potentially compromising vaccine efficacy. Regulatory bodies including the CDC and WHO mandate continuous temperature monitoring for vaccine cold chain management, requiring facilities to maintain detailed records of storage conditions. Non-compliance can result in costly vaccine waste, regulatory penalties, and compromised patient safety.

Challenges of Traditional Monitoring Methods

Traditional monitoring methods struggle to meet these stringent requirements:

- Manual temperature checks create gaps in documentation, leaving facilities vulnerable during audits.

- Paper logs are susceptible to human error, transcription mistakes, and potential data manipulation.

- When inspectors request proof of continuous compliance, incomplete records raise immediate red flags.

How Wireless Temperature Monitoring Systems Can Help

Wireless temperature monitoring systems transform compliance from a burden into an automated process:

- Continuous data capture creates unbroken temperature records without manual intervention.

- Automated audit trails timestamp every reading, creating tamper-proof documentation.

- Digital storage preserves years of temperature data for regulatory review.

- Instant deviation alerts enable immediate corrective action before vaccines are compromised.

The systems generate comprehensive reports that align with regulatory requirements for vaccine storage guidelines. Each temperature reading includes date, time, and sensor identification, creating the detailed documentation auditors expect. When temperature excursions occur, the system automatically logs the event duration, minimum and maximum temperatures reached, and response times.

Meeting the Demands of Health Departments and Accreditation Bodies

Facilities handling vaccines face increasing scrutiny from health departments and accreditation bodies. Wireless systems provide the documentation infrastructure needed to demonstrate continuous compliance. The technology eliminates the anxiety of surprise inspections by maintaining perpetual readiness with complete, accurate temperature histories readily available for review.

For organizations managing multiple storage units or locations, centralized monitoring ensures consistent compliance across all sites. Administrators can verify that every refrigerator and freezer meets cold chain management standards without physical site visits, streamlining oversight while maintaining rigorous adherence to protocols.

4. Do They Need More Accurate and Faster Temperature Sensing for Critical Applications?

Critical environments like medical freezers and pharmaceutical storage demand precision that basic sensor types simply cannot deliver. The difference between sensor technologies directly impacts how quickly and accurately temperature deviations are detected.

Thermistors: Superior Accuracy

Thermistors offer superior accuracy compared to basic dry contact switches, typically measuring within ±0.1°C to ±0.2°C. These sensors use resistance changes to detect temperature variations, providing specific numerical readings rather than simple on/off signals. Their rapid response time means they detect temperature shifts within seconds, not minutes.

Transducers: Exceptional Accuracy

Transducers represent another high-precision option, converting temperature into electrical signals with exceptional accuracy. These sensor types excel in environments where even fractional degree variations matter, such as:

- Ultra-low temperature freezers storing biological samples

- Vaccine refrigerators requiring strict +2°C to +8°C ranges

- Blood bank storage units

- Research laboratories with temperature-sensitive compounds

The Impact of Sensor Speed on Medical Freezers

Medical freezers storing critical medications or biological materials cannot afford the lag time of slower sensors. A delay of even five minutes in detecting a temperature rise could mean the difference between salvageable and compromised inventory. Basic dry contact switches might take 15-30 minutes to register a problem, while thermistors and transducers respond almost instantaneously.

Regulatory Requirements and Sensor Accuracy

The accuracy advantage becomes clear when considering regulatory requirements. Many pharmaceutical products have storage tolerances of just ±2°C. A sensor with ±1°C accuracy leaves virtually no margin for error, while thermistors with ±0.1°C accuracy provide reliable readings well within acceptable ranges.

Addressing Unexplained Product Degradation

Facilities experiencing unexplained product degradation despite “normal” temperature readings often discover their sensor types lack the precision needed. Upgrading to wireless systems with thermistors or transducers eliminates this blind spot, providing the accurate, real-time data that critical applications demand.

5. Is Remote Access to Temperature Data Essential for Their Operations?

Remote monitoring revolutionizes how organizations manage temperature-sensitive storage by eliminating the need for physical presence. Traditional systems store important data on-site, necessitating staff visits to check readings or download logs from data loggers. This results in monitoring gaps during off-hours, weekends, and holidays when facilities are unstaffed.

Real-time data access, facilitated by wireless systems, allows authorized personnel to view current temperatures from smartphones, tablets, or computers anywhere with internet connectivity. For instance, a pharmacy manager can verify vaccine refrigerator conditions from home at midnight. A laboratory supervisor traveling for a conference can monitor multiple freezers across different buildings simultaneously.

The shift to mobile temperature tracking addresses several operational challenges:

- 24/7 visibility without requiring staff to physically enter storage areas

- Multi-site management from a single dashboard for organizations with distributed locations

- Instant verification during audits or inspections without searching through paper logs

- Historical data review accessible immediately rather than waiting for manual downloads

Healthcare facilities storing temperature-sensitive medications particularly benefit from this capability. In the event of a weekend power outage, the on-call manager receives immediate alerts and can view exact temperature trends without driving to the facility. This enables informed decisions about whether to relocate inventory or dispatch emergency services. Furthermore, this kind of real-time access to patient care data is critical in ensuring the safety and efficacy of healthcare operations.

Research laboratories handling biological samples face similar challenges. A single freezer failure during a holiday weekend could destroy years of irreplaceable research materials. Wireless systems with remote access capabilities provide continuous oversight regardless of building occupancy, allowing researchers to respond within minutes rather than discovering problems days later.

The geographic flexibility of remote monitoring also supports growing operations. Organizations expanding to multiple locations can maintain centralized temperature oversight without proportionally increasing staff. A single quality assurance team can monitor dozens of sites across different cities, receiving alerts and reviewing data without travel requirements.

6. Have They Experienced Product Loss or Damage Due to Temperature Excursions?

Product loss from temperature excursions represents one of the most costly consequences of inadequate monitoring systems. When vaccines, medications, or biological samples experience temperatures outside their required range—even briefly—the financial impact can reach thousands of dollars per incident, not counting the potential harm to patients or research outcomes.

What Risks Come With Inadequate Temperature Control?

Temperature-sensitive products face multiple threats when monitoring systems fail to detect excursions quickly:

- Vaccines stored outside the +2°C to +8°C range lose potency, rendering them ineffective or potentially harmful.

- Pharmaceutical products may degrade chemically, creating compounds that compromise patient safety.

- Blood products and biological samples can undergo irreversible changes at the cellular level.

The spoilage risk extends beyond the immediate product loss. Organizations must:

- Investigate the extent of exposure across all affected inventory

- Document the incident for regulatory compliance

- Replace compromised products at full cost

- Notify patients or clients about potential impacts

- Face possible regulatory penalties or legal liability

A single freezer malfunction overnight can destroy an entire inventory of temperature-sensitive materials before staff arrive the next morning.

How Does Continuous Wireless Monitoring Enable Rapid Response?

Wireless temperature monitoring systems transform product loss prevention by detecting excursions within minutes rather than hours or days. The moment temperatures drift outside preset parameters, designated personnel receive instant alerts via text message or email, regardless of their location or the time of day.

This immediate notification creates a critical window for intervention. Staff can:

- Transfer products to backup storage units before damage occurs

- Identify and address equipment malfunctions in real-time

- Implement emergency protocols while products remain salvageable

- Document response times and actions for compliance records

The system’s continuous data logging provides precise timestamps showing exactly when an excursion began, how long it lasted, and whether products remained within safe limits. This documentation proves invaluable for determining whether inventory can be safely retained or must be discarded.

6 Signs You Need to Upgrade to Wireless Temperature Monitoring Systems become apparent when calculating the cost of even one preventable loss incident. Organizations that have experienced temperature-related product damage often discover that a wireless monitoring system pays for itself after preventing just

Conclusion

Why should organizations prioritize upgrading to wireless temperature monitoring systems?

The 6 Signs You Need to Upgrade to Wireless Temperature Monitoring Systems reveal critical gaps that wireless solutions address directly. Organizations facing delayed alerts, excessive manual workload, compliance pressures, accuracy concerns, remote access needs, or product losses gain immediate advantages through modern wireless technology.

What specific benefits justify the investment?

Wireless systems deliver measurable improvements across four essential areas:

- Enhanced accuracy through advanced sensor technologies like thermistors and transducers that detect temperature deviations within ±0.5°C

- Regulatory compliance with automated audit trails and continuous monitoring that meet vaccine cold chain requirements

- Operational efficiency by eliminating manual data collection and reducing staff time spent on temperature checks by up to 75%

- Risk mitigation through instant alerts that enable rapid response before temperature excursions cause irreversible product damage

How do wireless systems future-proof temperature management operations?

The upgrade benefits summary wireless system advantages future-proofing temperature monitoring extends beyond immediate problem-solving. Remote access capabilities support distributed operations and work-from-anywhere models. Automated data collection creates comprehensive historical records for trend analysis and predictive maintenance. Real-time notifications transform reactive temperature management into proactive protection.

Is now the right time to upgrade?

Organizations experiencing even one of these six signs should evaluate wireless temperature monitoring solutions. The cost of inaction—spoiled vaccines, failed audits, wasted staff hours, or compromised product integrity—typically exceeds the investment in modern monitoring technology. Wireless systems represent not just an upgrade but a fundamental shift toward reliable, efficient, and compliant temperature management that protects both products and reputation.

Click here for more Finding the Right Temperature Monitoring Solutions for Compliance